Turbine Oils Protection

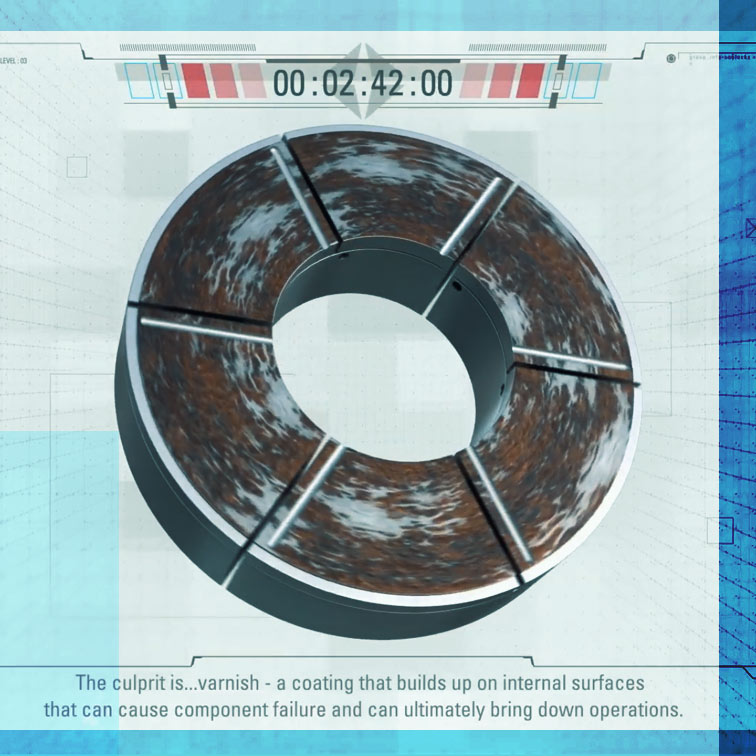

Protect against Varnish Buildup

Many reliability engineers see varnish buildup as just a way of life that can only be addressed after operating problems occur. But the cost of waiting to fix that problem is more than you’d think, because the related hidden costs can add up before you even realise you have a varnish problem in the first place.

GETTING AHEAD OF THE PROBLEM

The best way to prevent varnish from attacking your equipment is to detect it early and take decisive action. As we look more closely, a new problem begins to emerge—assumptions about varnish-related issues might be costing engineers more than they realise in the long run:

- Varnish isn’t always considered a top priority vs others needing immediate attention and efforts.

- Varnish is an issue that leads to other problems like valve stiction, reduced oil cooler performance, failure to start and trip event.

- The estimated ongoing maintenance costs to combat varnish build up: USD 40,000 per turbine, per year.

To defeat varnish, you first must understand it

How much do you really know about varnish?

Let’s take a deeper look at some of the ways varnish impacts your operation, including why it forms in the first place, which equipment types and operating conditions are more likely to experience varnish formation, and how some methods work—and don’t work—when you’re trying to halt varnish buildup in its tracks.

Are there different types of varnish?

Yes. And the treatment—or removal—of varnish depends on the type of varnish that has formed and how it was generated in the first place.

What are some of the most impactful costs associated with a reactive varnish approach that we might not realise are building up?

There are several examples of costs and fines associated with varnish buildup in combustion turbines. The costs may include chemical treatments, parts replacement for plugged filters, and the actual labour costs to replace those filters. Additionally, there may be fines and lost revenue for turbine trip events or failures to start.

How do we measure varnish formation or impact in between drains or flushing when the equipment is still running?

There are several laboratories that perform tests to identify the varnish precursors in the oil before varnish forms in the turbine systems. Some of these include membrane filter patch tests or colorimeter tests.

MEET OUR PROPRIETARY VARTECH™ SOLUTION

Find out how your business can benefit from our proprietary VARTECH solution — developed from rounds of rigorous innovation and testing by the experts at Chevron Lubricants.

LubeWatch® Oil Analysis Program

Track the performance of your turbine lubricants to optimise equipment life, oil replacement intervals, and help the precise scheduling of maintenance that reduces downtime and the risk of failure. Include this into your preventive maintanence program today.