VARTECH™ Industrial System Cleaner (ISC)

Clean without compromise

Turbines are at the heart of your operation. If they’re attacked by varnish, your production could halt.

Learn how VARTECH™ Industrial System Cleaner (ISC) utilizes proprietary technology to do the most thorough and efficient cleaning job without creating operational constraints.

HOW A VARNISH PROBLEM STARTS

High operating temperatures in your system deplete protective additives in your oils and cause it to degrade over time. The results—oxidation by-products, contaminants and more—can start to precipitate out of the oil. When they do, these deposits attach themselves to equipment surfaces and build up over time, forming a coating of varnish that quickly begins to do its dirty work.

The real business impacts

Varnish buildup reduces a lubricant’s heat transfer properties and causes your system to run hotter and hotter. The consequences won’t just threaten your equipment—they’ll hit you on your bottom line.

- De-rated equipment, unplanned shutdowns, inefficient operation

- Increased maintenance labor, management and spending

- Higher costs and lost profits for the business owner

The issue with conventional cleaners…

Chemical cleaning is the most common method to clean systems of varnish, with most conventional industrial system cleaners being applied at the end of oil life. But due to several compatibility problems in conventional cleaners, they can swell and damage seals, plug system filters and—if not removed in a timely manner— may redeposit the varnish in your system.

- Can cause critical component failures, system damage

- Contributes to lubricant performance degradation

- Requires a system flush

The Solution: A System component and lubricant-compatible cleaner

The experts at Caltex Lubricants have developed a new cleaning solution to help you protect equipment from varnish and ensure peak productivity in your operation - The VARTECH™ Industrial System Cleaner (ISC).

Eradicate varnish that has infiltrated your turbine system

When added to the in-service oil at its end-of-life, VARTECH™ ISC works quickly and effectively to help you restore equipment to peak performance for outstanding reliability and productivity. It’s quick, effective and easy to use.

Designed with triple-action varnish removal technology, it:

- Cuts through hard varnish to remove it as micro-sized varnish particles

- Captures varnish particles in a protective barrier to enable effective removal from the system without re-depositing on the equipment

- Provides compatibility with in-service oil for optimum operational flexibility and system performance during the cleaning cycle

VARTECH™ ISC helps prepare your equipment for fresh oil. A Caltex lubrication specialist can work with you to recommend an optimized cleaning cycle time to effectively remove sludge and stubborn, baked-on varnish from your system. However, if unexpected delays are encountered, you can feel confident knowing that the cleaner can temporarily remain in your system without damaging internal components.

Can I add VARTECH™ ISC to a lubricant to make it a varnish resistant oil?

No. Caltex lubricants with VARTECH™ Technology are specially formulated to incorporate varnish controlling properties into the lubricant. VARTECH™ Industrial System Cleaner is designed to clean systems and uses different formulations.

Can I use VARTECH ISC as a top-treat life-extender?

We does not recommend this approach as:

- Modern lubricants are high performing advanced technology formulations and the chemicals in the cleaner can adversely alter the balance of the formulation which may in turn cause unexpected lubricant upset over time,

- Varnish and other contaminant particles remain in the system until removed with the oil.

VARTECH ISC is designed as an end-of-oil-life cleaner precisely to avoid these issues. Its components are not tailored for long periods of operation such as the multiple years turbine oil is often in service.

Where can I buy VARTECH ISC?

VARTECH ISC is available through our network of lubricant distributors.

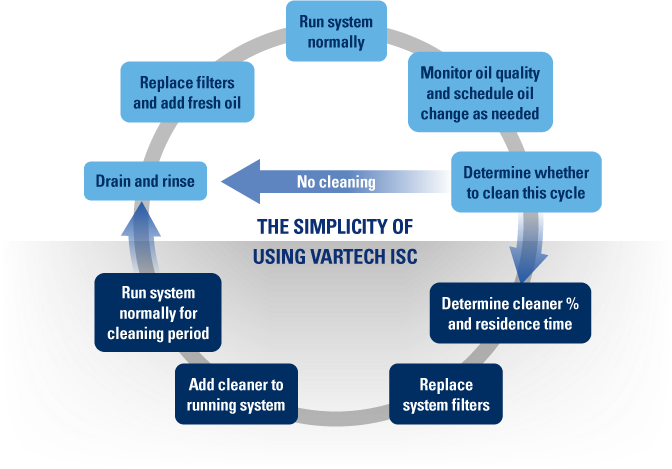

How often should I use the cleaner?

Many operators choose to use a chemical cleaner as part of every oil change process. Others choose to clean only when operational evidence of varnish deposits are present. Deliberate consideration of whether to clean or not should form part of the planning for every oil change.

Why should I drain effectively before refilling with fresh oil?

Old, degraded oil mixed into the refill oil will diminish the performance of the fresh oil. Residual cleaner will affect both the performance and life of the fresh oil. Some cleaners are so incompatible with fresh oil that they can reduce by ⅔ the expected life of the oil based on Rotating Pressure Vessel Oxidation Test (RPVOT) tests.

VARTECH ISC is specifically formulated to be compatible with turbine oils and so minimize the impact of residual cleaner on the fresh oil.

Do I have to rinse flush after cleaning?

Rinse flushing is a best practice for any oil change to completely remove old, degraded oil from all parts of the system, particularly when any of the following conditions exist:

- Prior to cleaning, the in-service oil was experiencing rapid oil degradation or was extremely degraded,

- Prior to cleaning, there were severe deposits in the system,

- More than 10% of the oil-cleaner mixture remains after draining.

Complete draining of all the old oil and cleaner mixture, including trapped mixture, helps mitigate the negative impacts on new oil performance and can reduce the need for flushing.

VARTECH ISC was formulated to be highly compatible with modern high-quality lubricants to minimize the risks of an incomplete drain or rinse.

Can I use the cleaner myself or do I need a service provider?

That depends on the complexity of your system and the capabilities of your team. Simply adding the cleaner, operating the system, and then performing a thorough oil change can be an effective approach. A service provider often brings valuable experience and can be very beneficial in confined space entry for reservoir wipe down, certified oil disposal, filter changes, and providing auxiliary heat for offline cleaning. They can also aid in determining cleaner residence durations and application concentrations.

When in doubt, contact our Sales Representatives to help guide you.

LubeWatch® Oil Analysis Program

Track the performance of your turbine lubricants to optimise equipment life, oil replacement intervals, and help the precise scheduling of maintenance that reduces downtime and the risk of failure. Include this into your preventive maintenence program today.